Screw Conveyors are highly versatile and efficient machines used for conveying a wide range of bulk materials, from powders and granules to flakes and aggregates. At Omkar Industries, our screw conveyors are engineered to provide reliable and continuous transport, minimizing manual labor and maximizing operational efficiency across various industries including food processing, chemicals, pharmaceuticals, agriculture, and waste management.

Flexible Screw Conveyors are highly adaptable and efficient for conveying materials in any direction, including vertically, horizontally, or at an incline, often navigating around fixed obstacles. Their simple design, consisting of a flexible screw rotating within a sealed tube, makes them ideal for handling dusty or sensitive materials while preventing spillage and contamination. They offer a cost-effective and versatile solution for complex layouts.

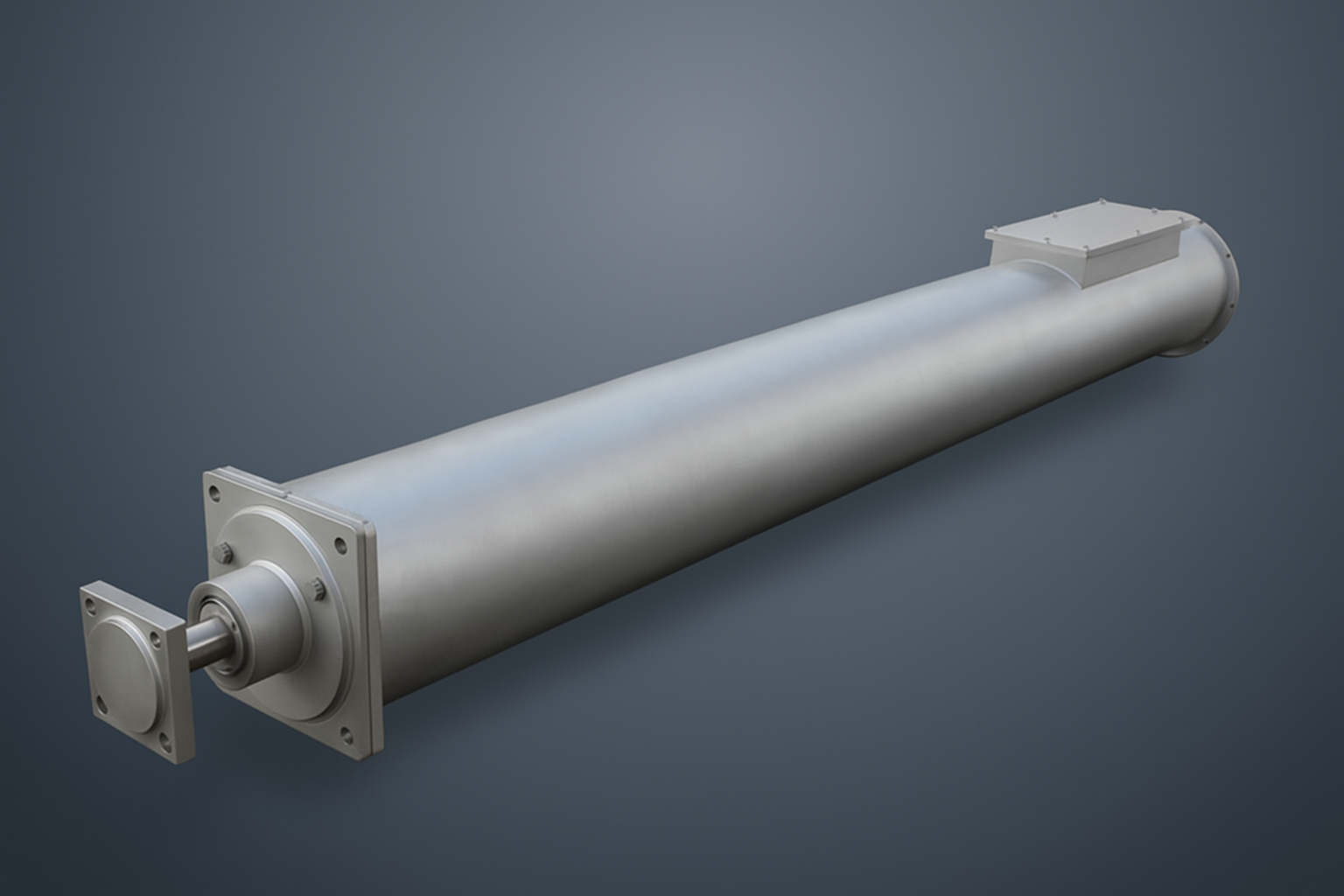

Tubular Screw Conveyors feature a fully enclosed tube design, making them an excellent choice for handling fine, dusty, or hazardous materials. They offer a compact and hygienic solution for conveying materials horizontally, vertically, or at an incline, ensuring a clean and safe operational environment, effectively preventing spillage and cross-contamination.

Vertical Screw Conveyors are ingeniously engineered to lift and transport materials vertically, significantly saving valuable floor space in industrial facilities. They are crucial for processes that require efficient material elevation, offering a compact and highly efficient solution for granular and powdered products, optimizing vertical material flow.

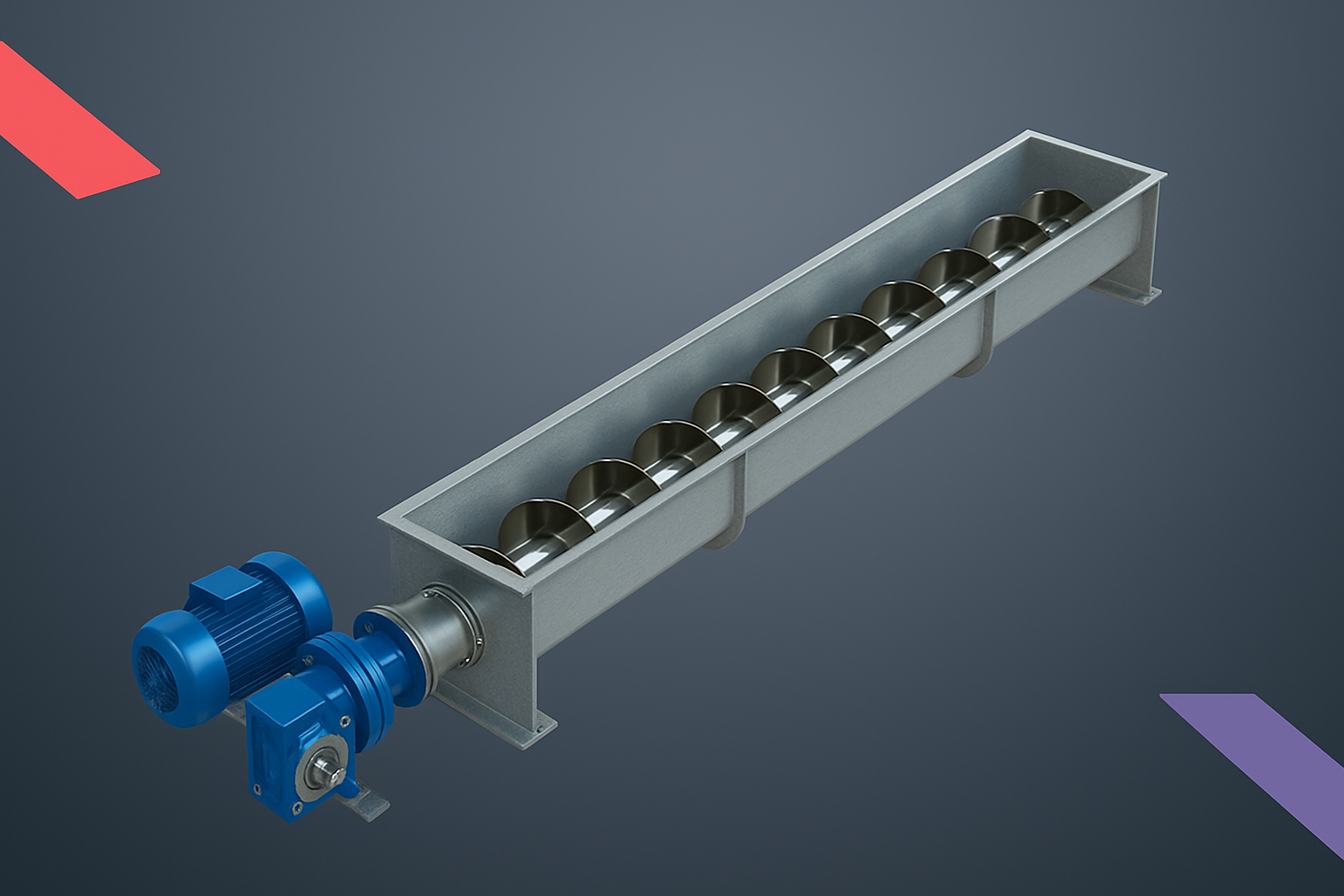

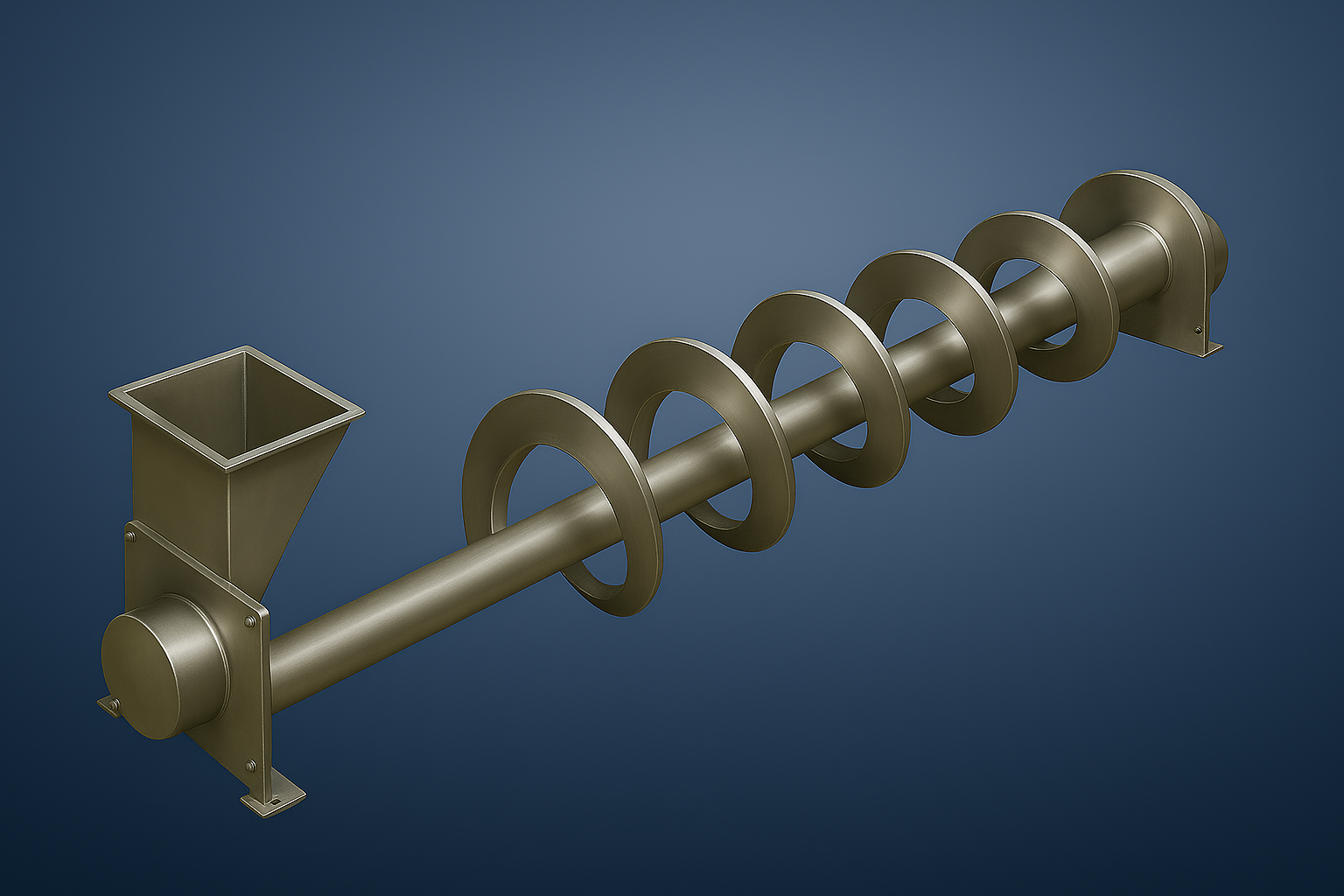

U-Trough Screw Conveyors are a common and robust choice for horizontal material handling. Their open trough design provides easy access for cleaning and maintenance, making them particularly suitable for various bulk solids, especially those that are free-flowing. They offer a reliable and straightforward solution for conveying materials efficiently in a horizontal plane.

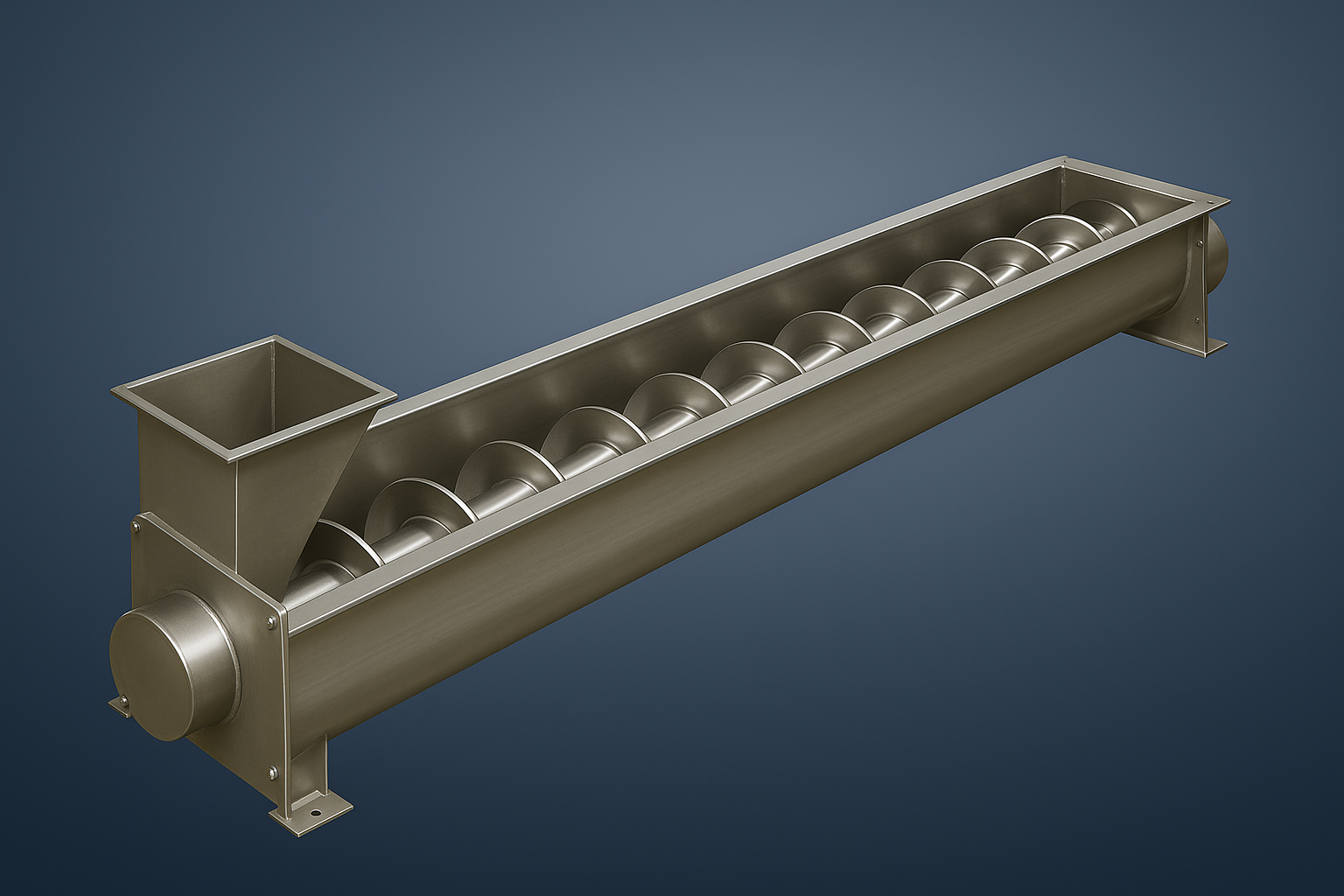

Our Stainless Steel Screw Conveyors are specially designed for industries with strict hygiene requirements, such as food, pharmaceutical, and chemical processing. Made from high-grade stainless steel, they offer excellent corrosion resistance and are exceptionally easy to clean, ensuring the highest level of product purity and compliance with industry standards.

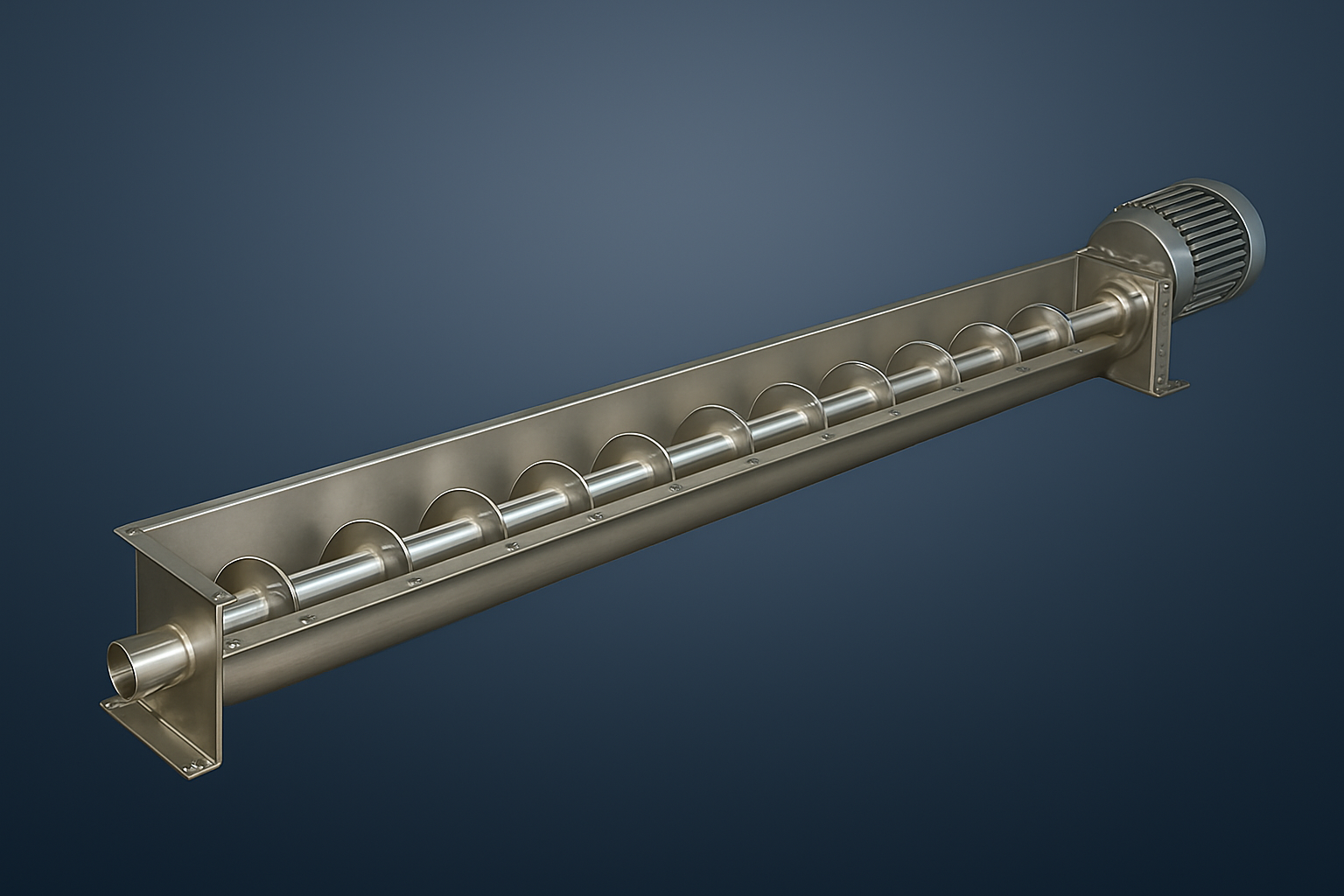

Shaftless Screw Conveyors are the ideal solution for handling difficult, sticky, or stringy materials that typically wrap around a central shaft. The absence of a central shaft effectively prevents material buildup, significantly reduces blockages, and allows for higher fill rates. This design makes them exceptionally efficient for challenging applications, ensuring continuous and trouble-free operation.

Address:

Omkar Industries

Sr.No 52/3 Maruti Nagar, Lane

No 4 Vadgoan Sheri, Pune 14.

Telephone:

+91 8805554868

+91 9890163007

Email:

mahaadeva23@gmail.com

mahaadeva@omkarindustry.com