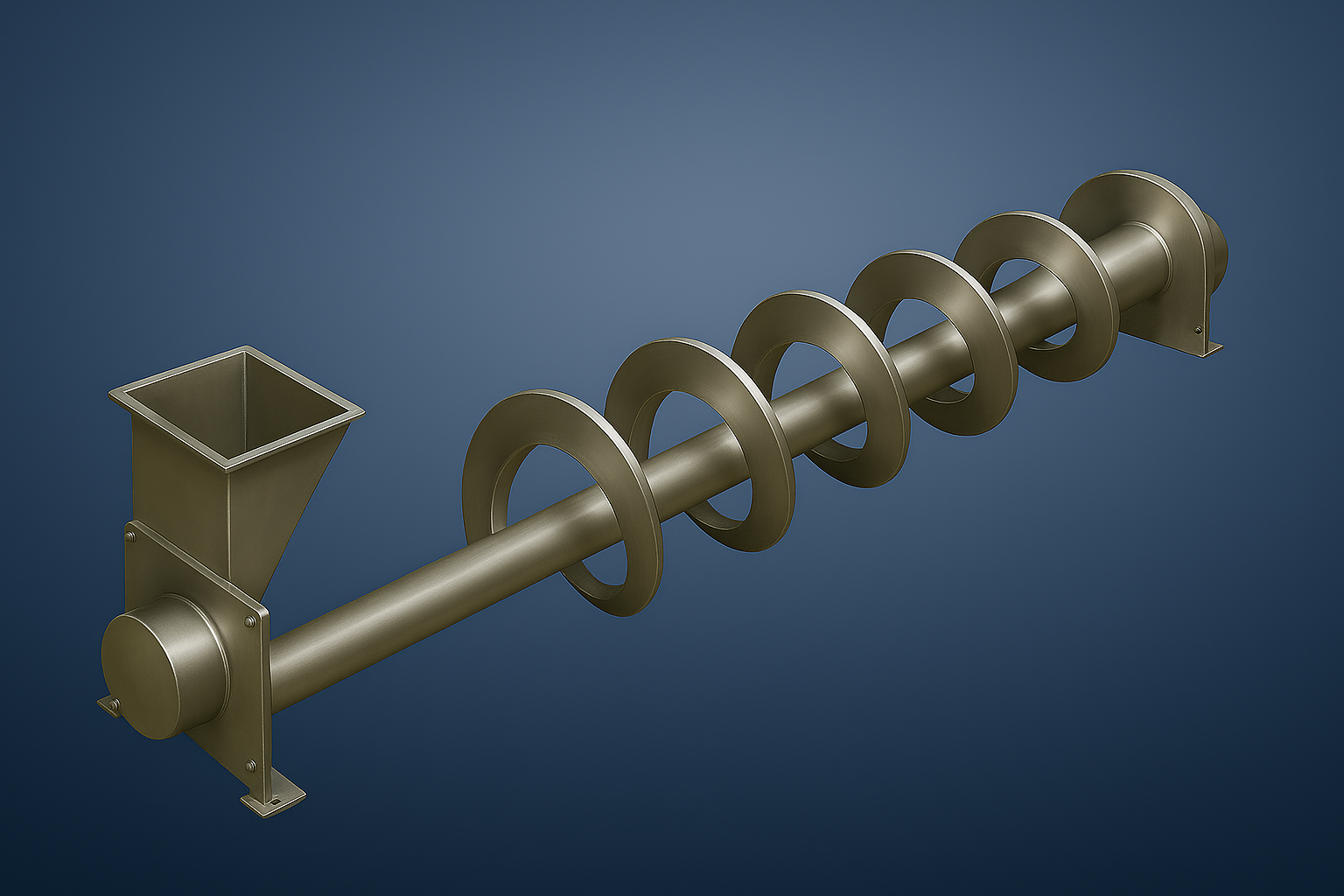

Our Shaftless Screw Conveyors are ingeniously engineered by Omkar Industries to provide an efficient and highly reliable solution for conveying difficult-to-handle materials. Unlike traditional screw conveyors that rely on a central shaft, the absence of this shaft in our design prevents material buildup, clogging, and ensures a cleaner, more consistent flow. This makes them exceptionally suitable for sticky, stringy, wet, or fibrous bulk solids that would typically cause issues in conventional conveying systems.

Key features and benefits of Omkar Industries' Shaftless Screw Conveyors include:

| Letter | Description | Dimensions | |

|---|---|---|---|

| in | mm | ||

| A | Inlet Opening Length | ||

| B | Inlet Opening Width | ||

| C | Outlet Opening Length | ||

| D | Outlet Opening Width | ||

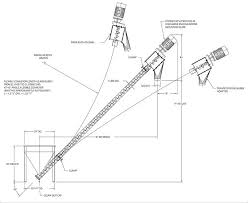

| Letter | Description | Dimensions | |

|---|---|---|---|

| in | mm | ||

| A | Trough Width | ||

| B | Spiral Diameter | ||

| C | Spiral Thickness | ||

| D | Overall Conveyor Length | ||

| E | Motor/Gearbox Power (HP/kW) | ||

| F | Capacity (m³/hr or TPH) | ||

| G | Material of Construction | ||

| H | Liner Material (if applicable) | ||

Address:

Omkar Industries

Sr.No 52/3 Maruti Nagar, Lane

No 4 Vadgoan Sheri, Pune 14.

Telephone:

+91 8805554868

+91 9890163007

Email:

mahaadeva23@gmail.com

mahaadeva@omkarindustry.com