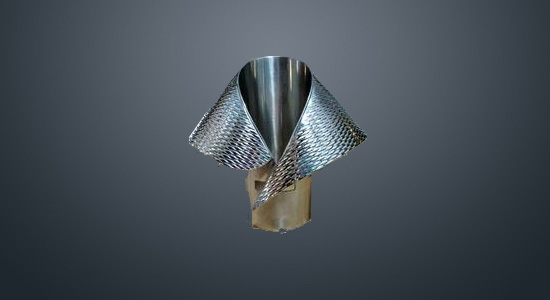

Our Forming Shoulders are precision-crafted components designed to optimize the film-forming process in various packaging machines, including Vertical Form Fill Seal (VFFS) systems. These shoulders play a critical role in guiding and shaping flexible packaging film into a tube before it is sealed, ensuring consistent bag dimensions, high-quality product presentation, and efficient operation of your packaging line.

Key features and benefits of Omkar Industries' Forming Shoulders include:

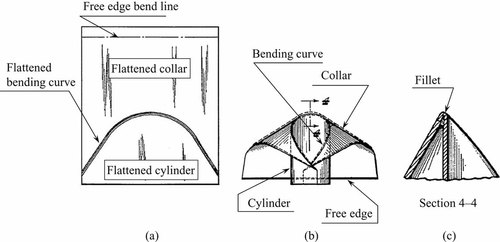

| Parameter | Description | Dimensions | |

|---|---|---|---|

| in | mm | ||

| A | Input Width (Flat Film) | ||

| B | Tube Width | ||

| C | Former Length | ||

| D | Overall Height | ||

| E | Infeed Angle | ||

| F | Tube Outlet Profile | ||

Our Forming Shoulders can be manufactured from various high-quality materials and with different surface finishes to suit your specific application, hygiene requirements, and film compatibility:

Contact us to discuss the best material and finish combination for your unique packaging needs, ensuring maximum efficiency and product quality.

Forming Shoulders are essential components in a wide range of industries for packaging diverse products on vertical form fill seal (VFFS) machines and other flexible packaging equipment:

Our expertise allows us to provide custom-designed Forming Shoulders that integrate seamlessly into your existing lines, optimizing performance across these varied applications.

Address:

Omkar Industries

Sr.No 52/3 Maruti Nagar, Lane

No 4 Vadgoan Sheri, Pune 14.

Telephone:

+91 8805554868

+91 9890163007

Email:

mahaadeva23@gmail.com

mahaadeva@omkarindustry.com