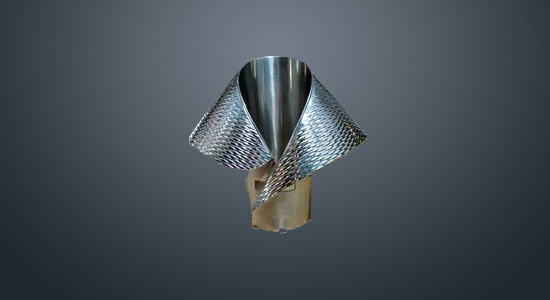

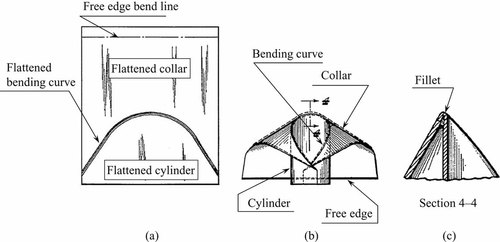

Our Form Shoulders are precision-engineered components vital for the efficient and accurate formation of bags and pouches in vertical form fill seal (VFFS) packaging machines. They are designed to smoothly guide and fold the packaging film into the desired shape before sealing, ensuring consistent and high-quality bag production. These critical parts play a significant role in minimizing film creasing and optimizing the overall packaging process.

Key features and benefits of Omkar Industries' Form Shoulders include:

| Parameter | Description | Dimensions | |

|---|---|---|---|

| in | mm | ||

| A | Input Film Width | ||

| B | Desired Bag Width | ||

| C | Shoulder Radius | ||

| D | Overall Length | ||

Our Form Shoulders can be manufactured from various high-quality materials and finishes to suit your specific application, hygiene requirements, and film compatibility:

Please specify your material and finish preferences in the inquiry form, along with your film type and operating conditions, for a custom solution that perfectly matches your needs.

Investing in Omkar Industries' Form Shoulders brings numerous advantages to your packaging operations:

Our Form Shoulders are engineered to be a reliable and efficient component, contributing significantly to the overall success of your packaging line.

Address:

Omkar Industries

Sr.No 52/3 Maruti Nagar, Lane

No 4 Vadgoan Sheri, Pune 14.

Telephone:

+91 8805554868

+91 9890163007

Email:

mahaadeva23@gmail.com

mahaadeva@omkarindustry.com